STEALTH EHC DRY GAS BLANKETING SYSTEM REMOVES WATER FOR FILL4LIFE FLUID

- Sania Munford

- Apr 17, 2022

- 2 min read

Updated: Aug 4, 2022

Maximizing Asset Life Through Technology

REMOVE WATER & EXTEND THE LIFE OF YOUR FLUID

FILL4LIFE™ PHOSPATE ESTER | KEEP YOUR FLUID CLEAN AND DRY

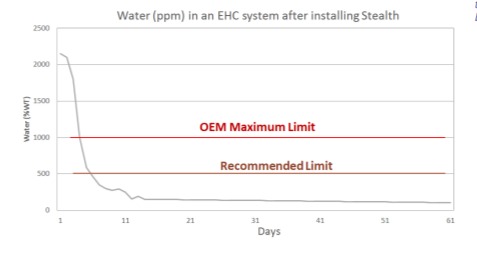

Hydrolysis is the main degradation pathway in phosphate ester systems. Because phosphate esters are hydroscopic, moisture control is a critical step in phosphate ester maintenance. Stealth EHCTM uses patented technology that removes moisture from phosphate ester fluids by introducing a steady stream of clean, dry air in the reservoir. This enhances reservoir breathing systems by actively and continuously purging and dehydrating the reservoir head space and removing water from the fluid.

STEALTH EHC BENEFITS

Removes dissolved moisture in fluid

Prevents the formation of corrosion in the reservoir

Eliminates the need to replace costly desiccant style breathers

Reduces acid formation by removing water

Minimizes the potential for particulate or water ingression through reservoir access points

Approved by GE Energy (Ref: GEK 4637f)

Uses no electricity, only compressed air. No moving parts.

Enables a Fill4Life Phosphate Ester Fluid

Stealth EHC uses the principle of mass transfer. When the humidity of the fluid is greater than that of the air (headspace), water molecules transfer to the dry air and the fluid becomes dry.

THE RESULTS ARE CLEAR…

FILL4LIFE PHOSPHATE ESTERS

STEALTH EHC + ENDURE IX

System cleanliness is restored with no outage requirements. Fluitec provides Stealth EHC to remove existing moisture and prevent any further water contamination, Endure IX to bring the fluid acidity back to ideal conditions.

HOW IT WORKS:

Our Stealth EHC system blankets your reservoir head space with our super-dry clean air. A low pressure air purge in the head space accomplishes two important tasks simultaneously: It extracts moisture from the fluid while excluding other contaminants from getting in the system. The result is exceptionally clean, dry fluid. The system is inexpensive to install, has no moving parts or electrical connections, and requires no maintenance. Quite simply, the Stealth EHC is the highest value contamination control technology you will install at your plant

ENDURE IX

Fluitec provides the optimum blend of media to target specific contaminants. There are media that specifically remove stronger acids, ones that remove weak acids (phenolic alcohols and varnish-forming molecules) and media that removes dissolved metals from the fluid. As the fluid makes contact with the blended Endure IX media the process of physisorption removes the contaminants. It is recommended to install Stealth EHC along with the Endure IX for optimum performance.

STEALTH EHC SELECTION GUIDE

STEALTH EHC SPECIFICATIONS

COMPONENT | MATERIAL/VALUE |

Prefilter Media Type | Borosilicate Glass |

Prefilter Housing | Polycarbonate, Zinc (Black) |

Particle Removal | 0.3 micron |

Max Oil Carryover @ 20° | C 0.01 ppm (0.01 mg/m3 |

Filter Condition | Visual Indicator (red when fouled) |

Coalescer Drain | Automatic Float Type |

Air Dryer Shell Material | Anodized Aluminum (Blue) |

Air Dryer End Cap Material | Nylon (Black) |

Fittings Material | Brass |

Seals Material | Buna-N |

Mounting Orientation | Vertical |

Air Inlet/Outlet | 1/4” NPT |

Mouting Bracket | 3/8”-16 Threaded Nut |

Maximum Operating Temp | 125° F (51° C) |

Maximum Operating Pressure | 116 psig (8 barg) |

Pressure Regulator | Dial Gauge |

Electrical Requirements | None |

Weight | < 5lbs (<3kg) |

HIGH THROUGHPUT STEALTH

COMPONENT | MATERIAL/VALUE |

AIR DRYER | |

Air Dryer Shell Material | Blue Aluminum |

Air Dryer End Cap Material | See dimensions table |

Air Dryer Mounting Orientation Standard Module | Any |

Maximum Operating Temperature | so·c l176°FI |

Maximum Operating Pressure | 12.5 barg 1180 psi) |

Typical Pressure Drop | 0.2 to 0.5 barg 13 to 7 psi) |

Required Filtration lit mounted on an oil-free compressor) | 0.1 micron coalescing filter |

Required Filtration lit mounted on a lubricated compressor | 0.01 micron coalescing filter |

OPTIONAL PREFILTER | |

Prefilter Media Type | Borosilicate Glass |

Prefilter Housing | Black Aluminum |

Mounting Orientation of Prefilter | Vertical |

Particle Removal | 0.01 micron |

Max Oil Carryover@ 20 'C | 0.01 mg/m3 |

PART NUMBER: CC-STL-FP15 PART

DESCRIPTION: DRY GAS BLANKETING SYSTEM, 5.3 CFM, 3.5 DIA

HELPING YOUR COST CONTROLS

MAXMIZING ASSET LIFE

Fluitec delivers a massive positive Environmental impact to your organization and your organizations sustainability. Beyond the financial savings and simply by doing business with Fluitec your organization will realize a reduction of Green House Gas (GHG) emissions.

Learn more at www.fluitec.com

Comments